The Opus-Two control system is an integrated control system - that means that pipe processing, combination action, crescendos, sforzandos, and anything else electrical is handled within one common control system. The control system does it all, and does it at very fast speeds. Read below to learn more about how the system works.

Assemble the system...

Opus-Two Control Systems are made up by plugging together modular components. The minimized number of components in a system results in a simple and easy to understand block layout.

One controller card can control up to 30 I/O cards - plug cards together to form chains. Add extender card kits to make chains longer.

At a console, add a display unit and wire to the controller. Memory level, transposer, record/play, extensive diagnostics, and more are controlled from the display.

...and then it's all software.

The vast majority of organs use the same features over and over again. Those features are common to all control systems and generally work the same. Pistons, reversibles, crescendos, sforzandos, and more are fairly common in the industry.

What sets control systems apart is when someone needs something that's a little different - if an expression matrix needs to be stored on a combination action, if page turn needs to be integrated into the control system, if the client wants a variety of expression couplers or flexible manual couplers, if a few flexible stops are needed, or even if the client wants tremolos to be adjustable and savable on each piston. These features are extremely easy to implement with Opus-Two, and very difficult to implement with any other control system. Once the configuration is built, the system simply works.

If a radically new idea exists that isn't in the software libraries, it can be hand-coded in the configuration file. Because of this flexibility, we have never told a client that we can't do something they want* and we have never told a client that they have to buy new hardware to make a requested feature work. Further, the Opus-Two systems that are installed have the potential to continue to service without being tethered to the manufacturer - a savvy client can continue to upgrade and make the changes they wish without consulting the manufacturer. Most of our larger organ builder clients simply buy the hardware and do their own configuration. We remain ready and willing to provide service and support to any client who wishes to either simply get a run-of-the-mill relay up and running or create the next big new thing.

This layout for a multi-chamber Next-Generation system shows how the console and chambers are interconnected modularly.

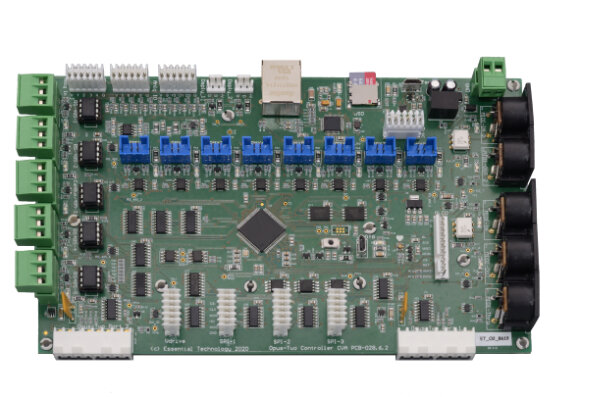

Controller Cards

All controllers feature one thing in common - the PipeBus port. This port is what allows Opus-Two controllers to communicate amongst one another. Unlike other control systems that require fiber optic tools, ethernet switches, and other complicated interconnects, this is simply a pair of wires with a shield. All controllers intended to go in a console have A/D inputs for potentiometers on them, a DisplayBus port, and MIDI ports.

It is worth noting that the controller cards in a given system are located in the places that the I/O cards are located (typically one in the console, one in each pipe chamber, etc.). The PipeBus connection to these cards is “parallel” – which means the PipeBus doesn’t have to go from card to card. This means there isn’t a certain order that they have to be connected, and wire doesn’t have to be run in circles around a church just to make the organ play. The PipeBus supports up to 256 controllers on one data bus (more than anyone will ever need).

The current standard controller (the CVA) features Two MIDI In, Two MIDI Out, MIDI Thru, 12 analog inputs (for swell or crescendo shoes), two DisplayBus port to support up to four displays, and an pair of Opus-Two ports, which allows up to 20 I/O cards to be chained on each. The Opus-Two port has not changed since the beginning of the system, and all Input, Output, and I/O cards are supported on every controller. The controller features a default of 100,000 levels of memory and 1,000 tracks of record and playback. These numbers are not set in stone and can easily change, please contact us for custom or larger requirements.

A smaller sibling has the same features, but has fewer ports. The CVE has a single pair of MIDI ports, a single display port, a single Opus-Two port (supporting up to 30 cards), and supports the same software libraries as the CVA (100,000 memory levels and 1,000+ tracks).

Display

Opus-Two displays come in two flavors, an inexpensive LCD screen and a more elegant VFD screen. Both are functionally identical, support 4×20 characters, and connect via the 3 wire DisplayBus connector on the controller card. Modern display units are compatible with CVA and CVE controllers. With a free software change, they will also work with legacy C-I, C-I-K, and C-IV controllers. Both the LCD and VFD display allow for the ‘control buttons’ to be wired directly into the display’s backboard for wiring convenience. These control buttons are pistons; we recommend that they are the same pistons installed in the piston slips for continuity.

I/O64 LED Cards

The majority of cards installed in a system are the input/output cards. One card does both input and output, and the majority of cards are supplied positive input/output. These can be changed to negative by us prior to shipping, or by a user in the field by following conversion instructions, which are available upon request. We also sell conversion kits with the correct number of chips and jumpers to make the process extremely easy.

Each pin on the card features a status LED which indicates the polarity of the pin. This also serves to indicate whether the pin is energized or not. You no longer need volt meters to troubleshoot inside consoles. The card can show you exactly what is working and what isn’t. If something is wired, and you aren’t sure where, the LEDs show you. If you want to check the wiring order of a keyboard, simply look at the LEDs as you play up the keyboard. The LED card absolutely revolutionizes how easy it can be to wire and troubleshoot a console, and must be experienced to be believed.

I/O64 cards get plugged in end-to-end to create a “card chain.” When it is time to move to a new row, our extender card kits make it very easy and reliable to connect the data from one row to the next.

The standard card uses Toshiba TBD62783APG chips for output high cards and the TBD62083APG for output low cards. The chips are rated for 500ma per pin. The part numbers for the driver chips are silkscreened onto the card for convenience.

What you get by assembling a system

Once a system is assembled by plugging the cards above together in the methods described, it can be programmed to do absolutely anything. As described in other sections of this web page, combination action, transposition, record/playback, MIDI interoperability, reversable controls, crescendos, and anything the organist can imagine are just a few lines of code away from reality. We supply a programming guide with our software toolsets and programming cables to help a technologically savvy user get into the swing of things, and we can do all the configuration for you if you are not comfortable doing it yourself. We have a network of dealers and savvy users throughout the country and are willing to connect you to one that is near you and may be able to help.

How to compare?

A frequent question with no good answer is how to compare Opus-Two to other control systems. Do you compare the buss speeds? Do you compare protocols? Controller memory? Unfortunately, none of these are good ways to compare control systems. Conceivably, a small pipe organ could simply have the keyboards wired to the wind chest, and this would probably be the fastest that it could be. The important measurement of a control system is whether you can tell that it has been inserted between the keyboard and the wind chest. We guarantee that Opus-Two is fast enough that you won’t be able to detect it. In fact, we allow the installer to see how long their configuration takes to execute and then optimize the cycle timing to run as fast as possible. We don’t just claim speeds, we let you see them and adjust them. And that’s all that really matters.

*"Because of this flexibility, we have never told a client that we can't do something they want" is a very powerful statement. We know our competitors constantly tell their clients no. We know that organ builders are tired of hearing that their relay can't do things the way they want. So why not try the relay that can do what you want?